Copyright © Dongguan Minz Rubber & Plastics Co., Ltd. All Rights Reserved. Site Map

- +86-13600262856

- lixiaoxia@dgminz.com.cn

- No. 4, New Industrial Road, Shipai Tangwei, Shipai Town, Dongguan City, Guangdong Province

Characteristics and uses of silicone

Silicone is a type of rubber. After vulcanization, silicone rubber is heat-resistant, cold-resistant, ozone-resistant, atmospheric aging-resistant and has good electrical insulation properties.

The disadvantages of silicone rubber are low tear strength and tear elongation, and large compression deformation.

It is suitable for making parts used in high temperature, low temperature, sunlight, atmosphere, ozone environment and electrical insulation parts.

Dimensional accuracy and recommended marking tolerances

The track material is an elastomer. Compared with plastic material, the direct influencing factors of its shrinkage rate are more and more complex, and the accuracy is more difficult to make than plastic parts. It should be fully considered in the specific design, and there should be no high precision.

If the basic size is too large and cannot meet the dimensional accuracy required in the design, the method of positioning column with substrate deformation can be used to solve it. Where there are requirements for dimensional accuracy, the design must leave room for convenient mold repair.

Etching text and pattern

Trademark patterns and text can be designed on the silicone substrate and molded at the same time when the product is molded. There are two types of groups and text on the product: convex and concave. Considering the convenience of mold processing, they are generally designed to be convex.

In order to facilitate the replacement of marks or models, the marking part can be designed as an insert when designing the mold. When the product model changes, only the insert of the marking part in the mold cavity can meet the need for marking replacement. As a design of this type of product parts, it should be allowed to have flash residues at the contour of the insert block of the marking part.

For conductive rubber, the stroke is generally 0.8 to 1.5 mm. the exhaust groove (i.e., air pit) is designed to prevent adsorption between the PCB board and the key action.

For a touch switch, the stroke depends on the stroke of the switch itself (and the stroke to prevent misoperation), as described later. If the substrate does not fit the PCB board, the air groove, a structural element, can be omitted.

There is a feel problem in button design. Different curves correspond to different feels. According to experience, when (FP-FC)/FP is between 40% and 60%, the feel is better.

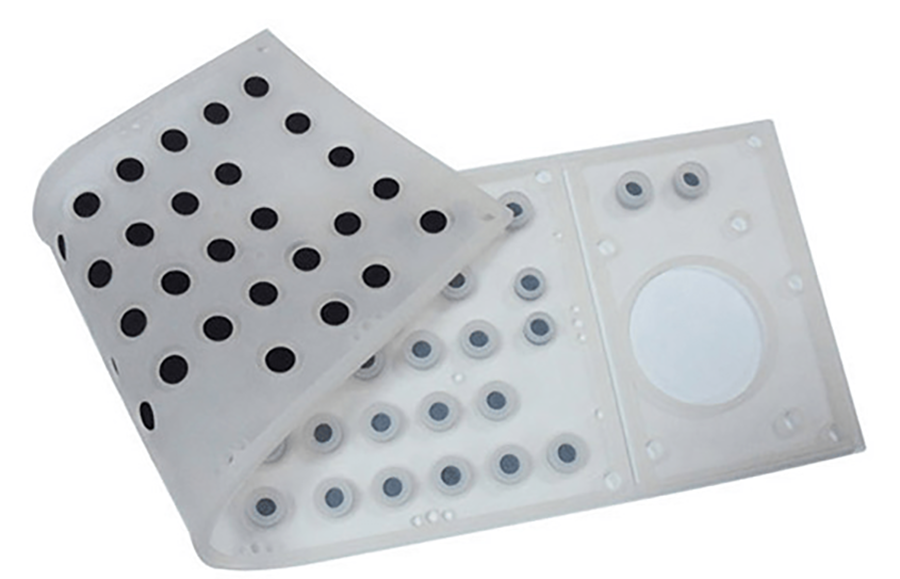

Typical structural forms and applications of buttons

According to the specific occasions where the buttons are used, as well as the specific requirements of the products on the life, pressing force, feel, etc. of the buttons, the structural forms and applications of the buttons are shown in the figure below.

The life of silicone buttons is directly related to the material and the inclined wall structure, and is determined according to the design requirements.

Reference for the life of silicone buttons of some products:

Remote controllers: 500,000 times.

Phone: 1 million times.

Laptops: 4 million to 5 million times.

Computer keyboards: 5 million to 10 million.

The life of silicone buttons for monitoring products is defined as more than 500,000 times.